Geotextile fabric for erosion control is a permeable geosynthetic material typically made from synthetic fibers polypropylene or polyester, geotextile fabrics come in three basic forms: woven, needle punched, or heat bonded process. The finished product is cloth-like, with a width of 4-6 meters and a length of 50-100 meters. The geotextile fabric for erosion control can help to mitigate the negative impact of soil erosion. Water erosion can be absolutely devastating to property. Sometimes the erosion happens very quickly and catastrophically due to a major storm event such as a hurricane or tropical storm. The geotextile should be loosely laid, free of tension, folds, and wrinkles. When used for dam protection, where currents acting parallel to the bank are the principal erosion forces, the geotextile fabric should be placed with the longer dimension (machine direction) in the direction of anticipated water flow. Geotextile fabric is widely used in geotechnical engineering such as dam protection, water conservancy, electric power, mines, highways and railways, it has the following features.

- Erosion control;

- Filter material for soil separation;

- Drainage materials for ore dressing in reservoirs and mines, and for foundations of high-rise buildings;

- Anti-scouring materials for river dams and slope protection;

- Reinforcement materials for road foundations of railways, highways and airports, and reinforcement materials for road construction in swamp areas;

- Anti-frost and anti-freeze insulation materials;

- Anti-cracking material for asphalt pavement;

- Geotextile fabric has good water conductivity, it can form a drainage channel inside the soil, and drain the excess liquid and gas from the soil structure.

- Effectively diffuse, transfer or decompose concentrated stress, and prevent soil from being damaged by external forces;

- Prevent mixing between the upper and lower layers of sand, gravel, soil and concrete;

- High water permeability. Under the pressure of soil and water, it can still maintain good water permeability.

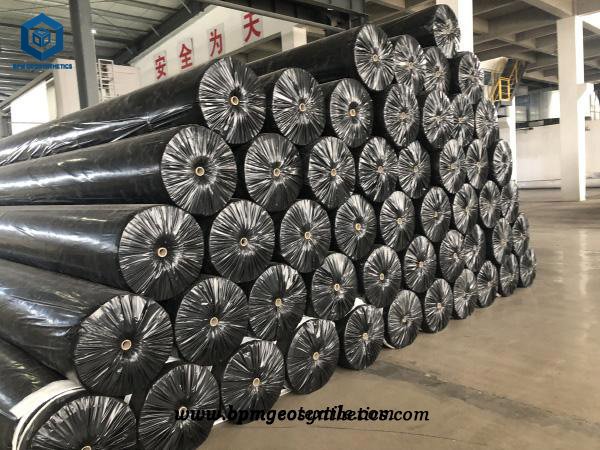

BPM customer is a distributor in Australia and has high requirements for geotextile products. This time he needed geotextile for a dam project. We have exported geosynthetics including geotextile to Australia for more than 7 years and have rich experience. First of all, we provide customers with geotextile samples of various specifications for customers to test. Then we provided customers with a variety of packaging methods, and the final customer chooses pvc pipe, PE film packaging. The customer was very satisfied with the test results. In the end, the customer reached a long-term cooperative relationship with us.

Specifications of Geotextile Erosion for Control in Australia

- Total quantity – 97,600 square meters

- Each roll size – 6m*100m

- Geotextile specification – 250gsm

About BPM

BPM manufactures and supplies many types of effective and states of the art geotextile, geomembrane, and other geosynthetics to over 36 countries. BPM geosynthetic products are widely used across a variety of industries including waste containment, water containment, aquaculture, industrial project, energy project and mining projects, etc. BPM main customers are from Australia, France, Sweden, UK, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, etc.