Smooth and Textured HDPE Géomembrane Liner for Mining Tailings Project DRC

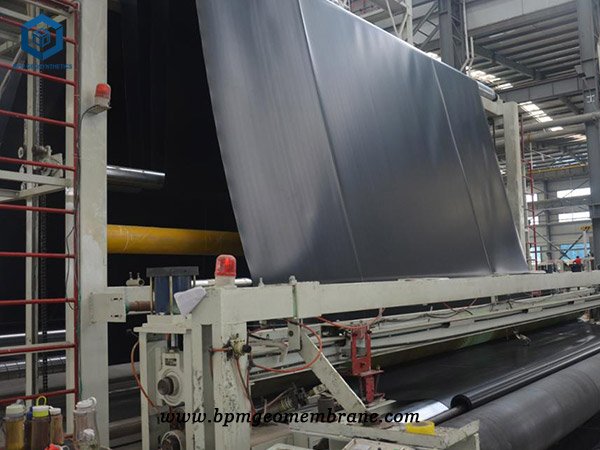

Smooth and textured HDPE géomembrane are the widely used geosynthetic materials for the anti-seepage lining projects in mines, ponds, dams, solid waste disposal sites and other industries projects because of its low permeability and strong corrosion resistance, etc. BPM smooth and textured HDPE géomembrane begin as raw polyethylene resin which is then processed into flexible HDPE liners. BPM HDPE geomembrane liner includes smooth HDPE géomembrane liner, textured HDPE geomembrane and composite geomembrane liner which can be made into different colors including black, white and double color composite liners are also available. The HDPE géomembrane liner has a higher UV resistance, suitable for outdoor environments. The textured HDPE géomembrane liner can be fabricated with single or double-sided surface to increase the friction coefficient to better suited to steep slopes and vertical engineering design needs, improve engineering stability.

Disposal of mine tailings is very important environmental concern for mining project. To control the release of tailing materials, a tailing dam or pond is created to contain the waste. As tailings commonly contain unvulcanized sulphide that can break down and release metals that can generate acidic conditions, they can represent a significant environmental hazard. Géomembraneliners are ideal geotechnical products used as the anti-seepage lining system for the tailing dams or ponds to protect the environment and prevent contamination of soils and groundwater tables.

BPM textured HDPE géomembrane manufacturing process is a two-step forming method, that is, the roughening of the geomembrane is carried out by blowing and roughening on the basis of the blown film, the rough spots are not easily peeled off, and the various detection values of the original geomembrane are not changed. When the surface is sprayed and the rough film is laid, the textured HDPE géomembraneand the base surface will form a small gap layer, which can enhance the anti-bearing deformation force of the géomembrane. The textured HDPE géomembrane is generally used in projects where the surface of the slope geomembrane requires a large friction coefficient. Rough geomembrane can be divided into single rough surface and double rough surface. With the increasingly serious environmental problems, the requirements for environmental protection related projects are getting higher and higher, especially in waste sanitary landfill, tail mining and petroleum. In the chemical industry category, the mine tailings contain heavy metal ions, toxic residual flotation reagents and acid waste water from the sulfur-containing minerals in the stripping waste rock. The impact on the environmental pollution and ecological damage of the mine and its surrounding areas will be long-lasting. The textured HDPE géomembrane can increase the friction coefficient and anti-slip function, which is more suitable for steep slope and vertical anti-seepage, and improve engineering stability. Here are several factors to consider when deciding which type of geomembrane to use in tailing project:

- Lower permeability

- High tear and puncture resistance (depending on the type of terrain)

- High chemical resistance

- Long Duration of project

- Good U.V exposure

Our South African customers had a bid of tailing project in DRC, they sent us the inquiry by email for many kinds of geomembrane products including 1.5mm textured HDPE géomembrane, 1.5mm hdpe smooth geomembrane and 5mm geocomposite with single 200gsm geotextile. We sent the price list, test report and loading details in the same day, BPM customers were satisfied with the our quick response. Several days later, they submitted the budget using our prices. About four days later, they updated the inquiry, they changed the single side textured HDPE géomembrane into double side textured HDPE géomembrane, then we offered the new prices, after that the customer asked us to sent them the MQC cert and spec sheet which attached with the quotation to the engineer for approval. Then BPM customers asked us to sent them the samples for testing, our high quality géomembrane products passed their test, after confirming some details and immediately placed the order with us.

Specifications of Smooth and Textured HDPE Géomembrane for Mining Tailings Project in DRC

- 1.5mm textured HDPE géomembrane -1,7170 square meters

- 1.5mm HDPE Smooth Geomembrane – 1,7143 square meters

- 5mm geocomposite with 200g geotextile on One side – 1, 7143 square meters

About BPM

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand HDPE geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our geomembrane products have been exported to over 36 countries.

BPM geomembranes mainly include Smooth Geomembrane HDPE Liner, Textured, Composite Geomembrane Liner, etc. BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.