HDPE Pond Liner Underlay for Starch Tail Sedimentation Tank in Shandong

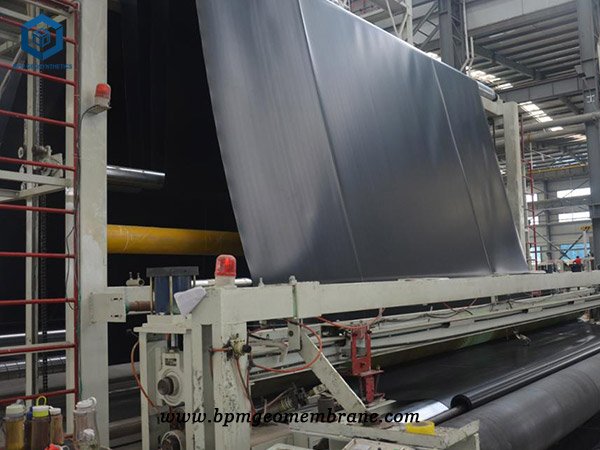

HDPE geomembrane pond liner underlay, also know as HDPE pond liner, is the lowest permeable synthetic membrane liner and geotechnical engineering materials ,which is made of finest quality high density polyethylene (HDPE) with specially formulated, virgin polyethylene resin, combined with specified quantity carbon black, antioxidant, anti-aging agent and UV resistance components,HDPE pond liner underlay is widely used for waste containment, mining and waste water containment applications.

Waterproofing tank is often built to contain starch tailings sedimentation which is generated in the starch production process, HDPE geomembrane pond liner underlay is often selected as the anti seepage lining system to avail leakage. The starch tailings sedimentation tank can realize the purification of water by utilizing the principle that the sedimentation velocity of the suspended impurity particles in the water flow is greater than the water flow velocity, or the sedimentation time is less than the time when the water flow flows out of the sedimentation tank.

In the grit chamber, the sedimentation principle can be used to remove inorganic impurities in the water. The sedimentation principle can be used in the primary sedimentation tank to remove suspended solids and other solids in the water. The sedimentation principle in the secondary sedimentation tank can be used to remove the activated sludge from the biological treatment effluent. In the concentration tank, the sedimentation principle is used to separate the water in the sludge, and the sludge is concentrated. In the deep treatment field, the sedimentation principle of the secondary settling tank and the flocculating agent can be used to remove the suspended solids in the water. The sedimentation tank includes five parts such as the influent zone, the sedimentation zone, the buffer zone, the sludge zone and the water discharge zone. In order to prevent soil and water from contamination,HDPE geomembrane pond liner underlay is often the ideal geotechnical anti seepage lining system due to its such properties as excellent chemical resistance, excellent impermeability, excellent UV resistance and stable low temperature embrittlement resistance, etc.

BPM client from Shandong province built a starch factory which is located in the rural area and based on the environment protection requirement, The client contacted BPM Geosynthetics company to order HDPE pond liner underlay for the sedimentation pond to contain the waste tailing generated in the starch production process.

According to client’s requirements, BPM engineer designed the lining solution with 1.5mm thickness black HDPE geomembrane pond Liner. At present, the commonly used starch waste water treatment method is physical lining protection method. Starch is insoluble in cold water, and the suspended solids in the waste water can be precipitated directly by physical precipitation. Generally, a sedimentation pond is applied. Starch waste water contains protein, starch, sugar and suspended matter. It is a highly dispersed hydrophilic colloid. This colloid is generally stable. When an anaerobic reaction occurs in the pool, the organic acid produced reduces the PH of the waste water and is in colloid. The protein in the state will form floccules and precipitate, which can improve the separation effect. The low permeability of HDPE geomembrane pond liner underlay allows for better storage and precipitation of waste water. The geotextile is underlaid the geomembrane pond liner to prevent from the destruction of clods and stones at the bottom of the sedimentation pond. Compared with traditional concrete, asphalt and compacted clay, smooth geomembrane pond liner underlay has proven to be far more cost effective, environmentally safe, excellent durable, chemically resistant, fast deployment and easy transportation.

BPM is equipped with very professional installation technicians, during the installation process, the constructor lays the non woven geotextile on the bottom of the sedimentation pond and then lays the geomembrane pond liner. The overlap width of the edge of the geomembrane pond liner underlay is about 12 cm. If the overlap width is too large, soldering is inconvenient. After the edge lap joint process is completed, the temperature of the machine to be welded reaches 400℃-450℃, and welding is performed.

Specifications of HDPE Pond Liner Underlay for Starch Tail Sedimentation Tank

- Total HDPE Pond Liner underlay quantity – 9000 square meters

- Each roll size – 7m*50m

- HDPE Liners Thickness – 1.5mm

About BPM

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand HDPE geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our geomembrane products have been exported to over 36 countries.

BPM geomembranes mainly include Smooth Geomembrane HDPE Liner, HDPE Textured Geomembrane, Composite Geomembrane Liner, etc. BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.